Some notes on laser cutting.

The laser cutter I used is an 80 watt model. The strength of the cut is determined by two parameters: power (as a percent of maximum) and speed (in mm per second). The manual listed a recommended setting for cutting 1/8″ basswood (50% power, 15 mm/s), and a recommended setting for engraving (14% power, 350 mm/s).

I tried the engrave and it worked fine, but I was worried that the cut setting might be too strong. I was right. For 1/8″ basswood I found 50% and 50 mm/s speed to cut just through. For my 3/16″ sheet the setting I found was 50% power and 30 mm/s speed. And for the 1/32″ sheet it was 50% power and 200 mm/s speed. If I had more time I would have experimented with other power settings, but I went ahead with the settings that I knew would work.

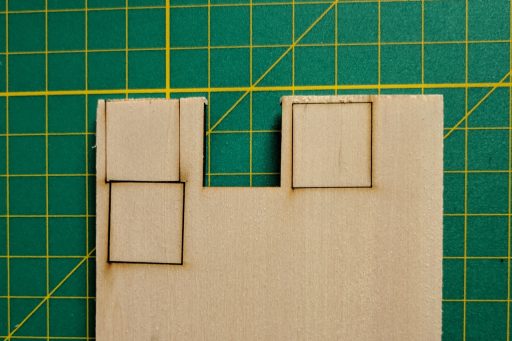

Some test cuts shown below.

After cutting the pieces, I tried a quick test fit and discovered that there was some wobble. I had made a rookie mistake: I didn’t account for the thickness of the material cut away by the laser and just assumed a perfect zero thickness line. My later measurements show the laser line is about .3 mm in width. That’s small, but enough that the pieces don’t slide together perfectly. I’d rather not revise my design and recut, so I’ll just be careful about making sure the bulkheads are perpendicular to the keel when I glue them in.

Another thing I noticed is that some curved cuts have a wavy rather than smooth line. This is most noticeable on the transom pieces cut from the 1/32″ sheet. I have two theories about why this happened. First, it could be related to how I had to save splines as polylines (details in one of my earlier updates). Or it could be a result of vibrations. I did nothing to hold the wood sheets onto the bed while they were being cut, so they may have been moved by vibrations from the machine. Anyway, the wavy lines can be sanded down smooth, so I think it will be ok.

Finally, I noticed that the text labels on the pieces were cut very deep. Fairing and reference lines were fine. The issue with the text was a consequence of how I added the text. In Inkscape, I added the text using a san serif font then used Inkscape’s object to path tool to convert the text into vector graphics. However, when they were engraved, the laser went over and over the text area to “fill in” the text, causing it to cut some or all the way through the wood. Fortunately, it happens in small enough areas that the model won’t be affected. In the future, I should use simpler vector text.