Using 1/16″ x 1/16″ strips, I have filled in part of the counter. It’s clear that I’ll need some filler to patch the gap between the hull planks and the counter planks.

Next, I want to glue on the transom end pieces and then I will be able to fill in the remaining space. My transom end pieces are three laser cut pieces, 1/32″ thick, which bend easily. The three pieces will be sandwiched together to form the transom shape with its recesses.

However, before I attach those pieces, I should put the windows in place.

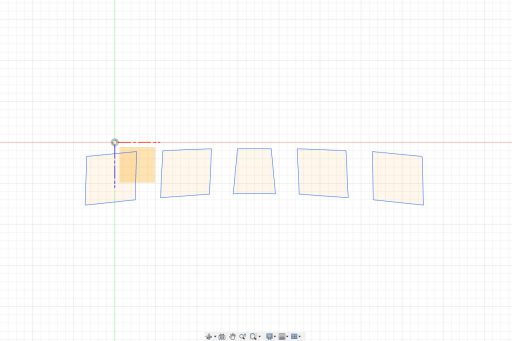

Here are the window shapes in Fusion 360.

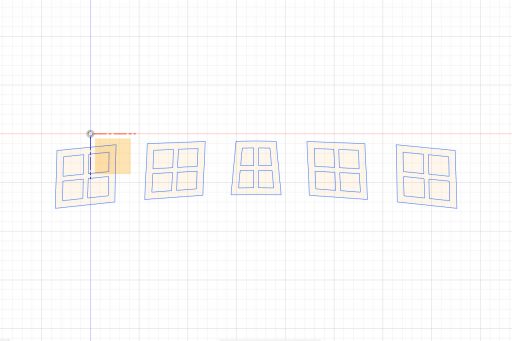

Panes for the windows are added.

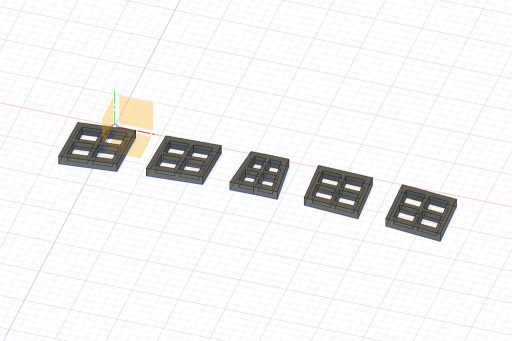

And the shapes are extruded.

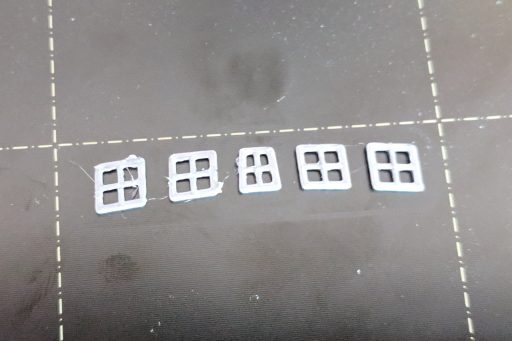

Saved and 3D printed.

The pieces are glued in and painted white.

And here is how it looks all assembled.