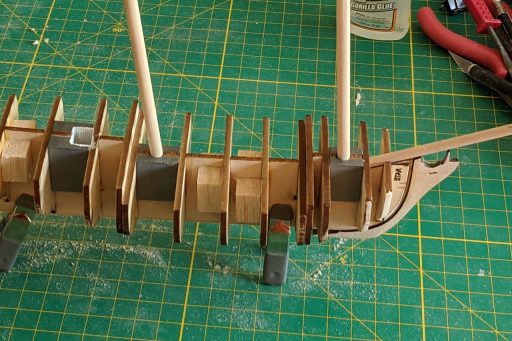

On the false keel, the cutouts for the masts are simple notches. The notches establish the forward and back angle, but do nothing to prevent side to side movement.

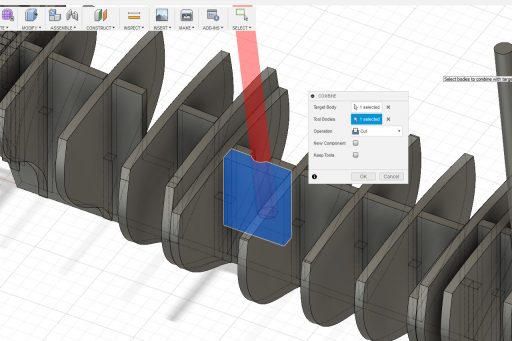

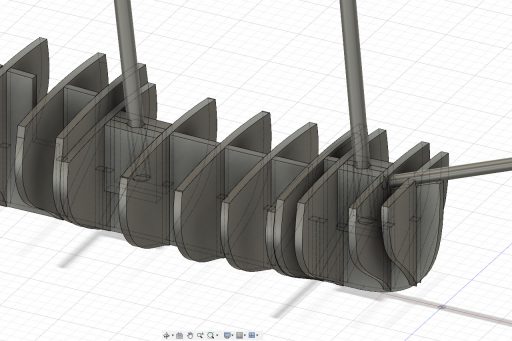

Let’s go back to Fusion 360 and imagine a part that fits on either side of the mast to hold it in the correct position. This is done in Fusion 360 by creating a little block and then subtracting the mast shape from it. The block is sized to fill the space between the bulkheads, so it also acts as a filler block to reinforce the bulkheads.

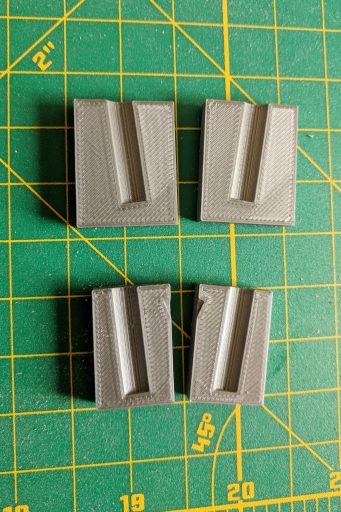

A total of four pieces are designed, two per mast.

And then they are 3D printed.

Here are the pieces in place. The dowels for the masts and bowsprit have been test-fit into their respective holes. I also 3D printed the aft hatch opening. It was created with a texture and painted to simulate the white wood paneling of the interior of the ship. Also, at the point this picture was taken, I had glued on the stem piece.